Toyota RAV4 (XA40) 2013-2018 Service Manual: Disassembly (2006/01- )

- Remove front axle inboard joint boot no. 2 Clamp

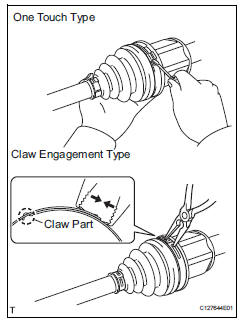

- One touch type: using a screwdriver, remove the inboard joint boot clamp, as shown in the illustration.

- Claw engagement type: using needle-nose pliers, remove the inboard joint boot clamp, as shown in the illustration.

- Remove front axle inboard joint boot clamp

- One touch type: using a screwdriver, remove the inboard joint boot clamp, as shown in the illustration.

- Claw engagement type: using needle-nose pliers, remove the inboard joint boot clamp, as shown in the illustration.

- Remove front axle inboard joint boot

- Remove the boot from the inboard joint.

- Remove front drive inboard joint assembly lh

- Remove any old grease from the inboard joint.

- Put matchmarks on the inboard joint and outboard joint shaft.

Notice:

Do not punch the marks.

- Remove the inboard joint from the outboard joint shaft.

- Using a snap ring expander, remove the shaft snap ring.

- Put matchmarks on the outboard joint shaft and tripod joint.

Notice:

Do not punch the marks.

- Using a brass bar and hammer, tap out the tripod joint from the outboard joint shaft.

Notice:

Do not tap the rollers.

- Remove the inboard joint boot.

- Remove front drive inboard joint assembly rh

Hint:

Use the same procedures described for the lh side.

- Remove front drive shaft damper clamp lh

- One touch type: using a screwdriver, remove the drive shaft damper clamp, as shown in the illustration.

- Claw engagement type: using needle-nose pliers, remove the drive shaft damper clamp, as shown in the illustration.

- Remove front drive shaft damper lh

- Remove the front drive shaft damper from the outboard joint shaft.

- Remove front axle outboard joint boot no. 2 Clamp

- Using a screwdriver, remove the outboard joint boot clamp, as shown in the illustration.

- Remove front axle outboard joint boot clamp

- Using a screwdriver, remove the outboard joint boot clamp, as shown in the illustration.

- Remove front axle outboard joint boot

- Remove the outboard joint boot from the outboard joint shaft.

- Remove any old grease from the outboard joint.

- Remove front drive shaft hole snap ring lh

- Using a screwdriver, remove the hole snap ring.

- Remove front drive shaft dust cover lh

- Using sst and a press, press out the shaft dust cover.

Sst 09950-00020

Notice:

Be careful not to drop the inboard joint.

- Remove front drive shaft dust cover rh

Hint:

Use the same procedures described for the lh side.

- Remove drive shaft bearing case (for rh)

- Using a screwdriver, remove the bearing case snap ring.

- Using a press, press out the drive shaft bearing case.

Hint:

Be careful not to drop the inboard joint.

- Remove front drive shaft dust cover (for rh)

- Using sst and a press, press out the drive shaft dust cover.

Sst 09950-00020

Notice:

Be careful not to drop the inboard joint.

- Remove front drive shaft bearing

- Using a snap ring expander, remove the snap ring.

- Using sst and a press, press out the drive shaft bearing.

Sst 09527-10011

- Remove the bearing case snap ring.

Disassembly (2005/11-2006/01)

Disassembly (2005/11-2006/01)

Remove front axle inboard joint boot no. 2 Clamp lh

One touch type:

Using a screwdriver, remove the inboard joint

boot clamp, as shown in the illustration.

Claw engagement t ...

Reassembly (2005/11-2006/01)

Reassembly (2005/11-2006/01)

Install drive shaft bearing case subassembly

Using sst and a press, press in the drive shaft

bearing case to the inboard joint rh.

Sst 09527-10011, 09710-04081

Notice:

The bearing ...

Other materials:

Rear speed sensor (for 4wd)

Components

Removal

Hint:

Use the same procedures for the lh side and rh side.

The procedures listed below are for the lh side.

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery termin ...

Customize parameters

Hint:

The following items can be customized.

Notice:

When the customer requests a change in a function,

first make sure that the function can be customized.

Be sure to make a note of the current settings before

customizing.

When troubleshooting a function, first make sure that

the fu ...

Washer motor

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

Remove washer inlet sub-assembly

Remove th ...