Toyota RAV4 (XA40) 2013-2018 Service Manual: Disassembly (2005/11-2006/01)

- Remove front axle inboard joint boot no. 2 Clamp lh

- One touch type:

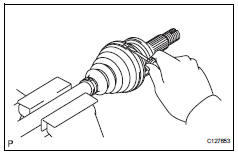

- Using a screwdriver, remove the inboard joint boot clamp, as shown in the illustration.

- Claw engagement type:

- Using needle-nose pliers, remove the inboard joint boot clamp, as shown in the illustration.

- Remove front axle inboard joint boot no. 2 Clamp rh

Hint:

Use the same procedures described for the lh side.

- Remove front axle inboard joint boot clamp lh

- One touch type:

- Using a screwdriver, remove the inboard joint boot clamp, as shown in the illustration.

- Claw engagement type:

Using needle-nose pliers, remove the inboard joint boot clamp, as shown in the illustration.

- Remove front axle inboard joint boot clamp rh

Hint:

Use the same procedures described for the lh side.

- Remove front axle inboard joint boot

- Remove the boot from the inboard joint.

- Remove front drive inboard joint assembly lh

- Remove any old grease from the inboard joint.

- Put matchmarks on the inboard joint and outboard joint shaft.

Notice:

Do not punch the marks.

- Remove the inboard joint from the outboard joint shaft.

- Using a snap ring expander, remove the shaft snap ring.

- Put matchmarks on the outboard joint shaft and tripod joint.

Notice:

Do not punch the marks.

- Using a brass bar and hammer, tap out the tripod joint from the outboard joint shaft.

Notice:

Do not tap the rollers.

- Remove the inboard joint boot.

- Remove front drive shaft damper clamp lh

- One touch type:

- Using a screwdriver, remove the drive shaft damper clamp, as shown in the illustration.

- Claw engagement type:

Using needle-nose pliers, remove the drive shaft damper clamp, as shown in the illustration.

- Remove front drive shaft damper lh

- Remove the front drive shaft damper from the outboard joint shaft.

- Remove front axle outboard joint boot no. 2 Clamp lh

- Using a screwdriver, remove the outboard joint boot clamp, as shown in the illustration.

- Remove front axle outboard joint boot clamp lh

- Using a screwdriver, remove the outboard joint boot clamp, as shown in the illustration.

- Remove front axle outboard joint boot

- Remove the outboard joint boot from the outboard joint shaft.

- Remove any old grease from the outboard joint.

- Remove front drive shaft hole snap ring lh

- Using a screwdriver, remove the hole snap ring.

- Remove front drive shaft dust cover lh

- Using sst and a press, press out the shaft dust cover

Sst 09950-00020

Notice:

Be careful not to drop the inboard joint

- Remove front drive shaft dust cover rh

Hint:

Use the same procedures described for the lh side.

- Remove drive shaft bearing case

- Using a screwdriver, remove the bearing case snap ring.

- Using a press, press out the drive shaft bearing case.

Hint:

Be careful not to drop the inboard joint

- Remove front drive shaft dust cover

- Using sst and a press, press out the drive shaft dust cover.

Sst 09950-00020

Hint:

Be careful not to drop the inboard joint

- Remove front drive shaft bearing

- Using a snap ring expander, remove the snap ring.

- Using sst and a press, press out the drive shaft bearing.

Sst 09527-10011

- Remove the snap ring.

Removal

(2006/01- )

Removal

(2006/01- )

Remove front wheel

Drain automatic transaxle fluid

Drain the automatic transaxle fluid for u140f (see

page ax-147).

Drain the automatic transaxle fluid for u241e (see

page ax-146).

...

Disassembly (2006/01- )

Disassembly (2006/01- )

Remove front axle inboard joint boot no. 2 Clamp

One touch type:

using a screwdriver, remove the inboard joint boot

clamp, as shown in the illustration.

Claw engagement type:

usin ...

Other materials:

Trailer towing

Your vehicle is designed primarily as a passenger-and-load-carrying

vehicle. Towing a trailer can have an adverse impact on

handling, performance, braking, durability, and fuel consumption.

For your safety and the safety of others, you must not overload

your vehicle or trailer. You must also e ...

Occupant classification sensor power supply circuit malfunction

Description

The occupant classification sensor power supply circuit consists of the

occupant classification ecu and

the occupant classification sensors.

Dtc b1793 is recorded when a malfunction is detected in the occupant

classification sensor power

supply circuit.

Wiring diagram

...

Power steering ecu communication stop mode

Description

Wiring diagram

Inspection procedure

Notice:

Turn the ignition switch off before measuring the resistances of the

main wire and the branch

wire.

After the ignition switch is turned off, check that the key reminder

warning system and light

reminder warning system ...