Toyota RAV4 (XA40) 2013-2018 Service Manual: Evaporative emission control system leak detected

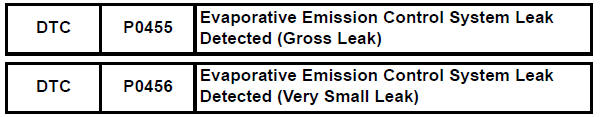

Dtc summary

Description

The description can be found in the evap (evaporative emission) system (see page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

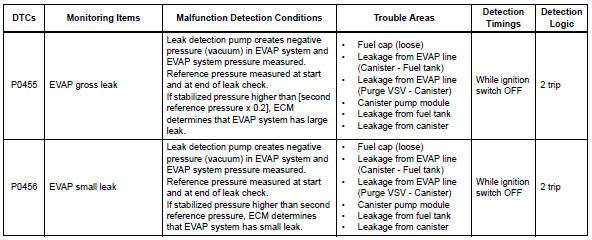

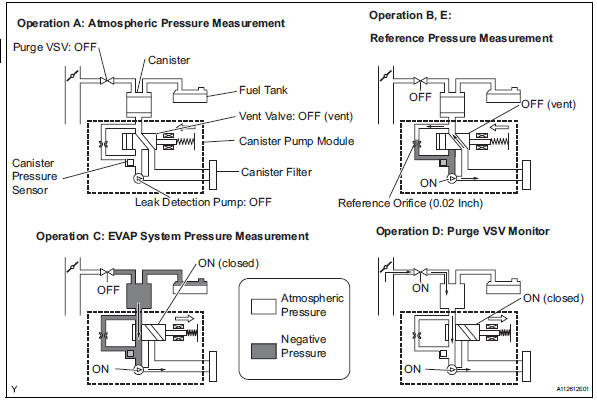

Monitor description

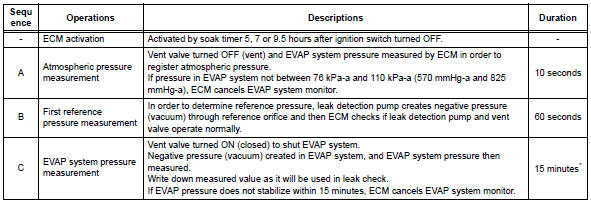

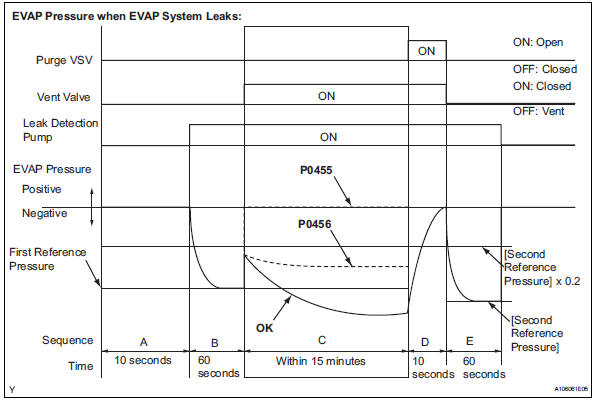

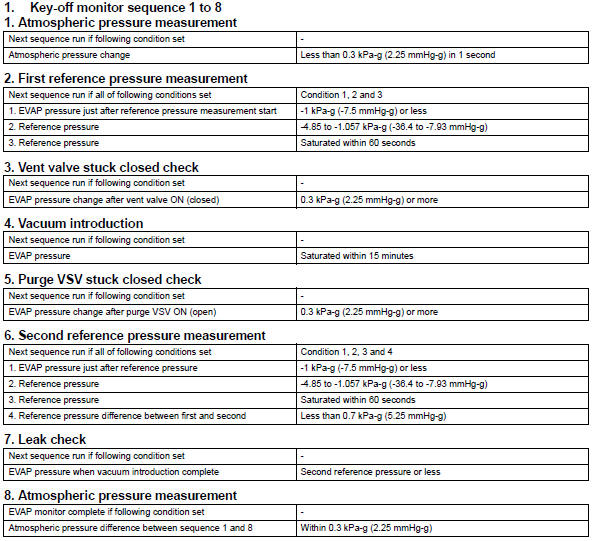

5 Hours* after the ignition switch is turned off, the leak detection pump creates negative pressure (vacuum) in the evap system. The ecm monitors for leaks and actuator malfunctions based on the evap pressure.

Hint:

*: If the engine coolant temperature is not below 35°c (95°f) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35°c (95°f) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 Hours later.

*: If only a small amount of fuel is in the fuel tank, it takes longer for the evap pressure to stabilize.

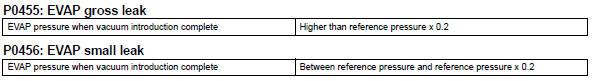

- P0455: evap gross leak

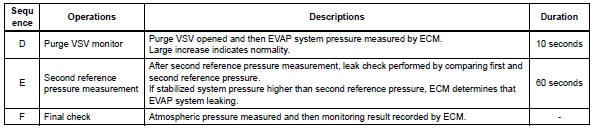

In operation c, the leak detection pump creates negative pressure (vacuum) in the evap system and the evap system pressure is measured. If the stabilized system pressure is higher than [second reference pressure x 0.2] (Near atmospheric pressure), the ecm determines that the evap system has a large leakage, illuminates the mil and sets the dtc (2 trip detection logic).

- P0456: evap very small leak

In operation c, the leak detection pump creates negative pressure (vacuum) in the evap system and the evap system pressure is measured. If the stabilized system pressure is higher than the second reference pressure, the ecm determines that the evap system has a small leakage, illuminates the mil and sets the dtc (2 trip detection logic).

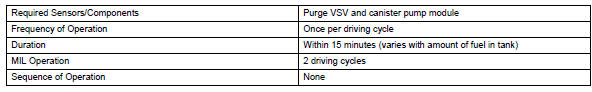

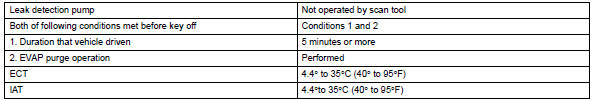

Monitor strategy

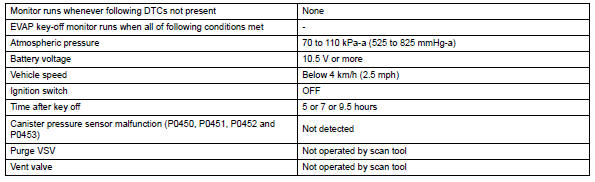

Typical enabling conditions

Typical malfunction thresholds

Monitor result

Refer to checking monitor status (see page es-17).

Evaporative emission control system pressure sensor

Evaporative emission control system pressure sensor

Dtc summary

Hint:

The canister pressure sensor is built into the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see

page es ...

Vehicle speed sensor "A"

Vehicle speed sensor "A"

description

The speed sensor detects the wheel speed and sends the appropriate signals to

the skid control ecu.

The skid control ecu converts these wheel speed signals into a 4-pulse signal ...

Other materials:

Exhaust gas precautions

Harmful substance to the human body is included in exhaust

gases if inhale.

Caution

Exhaust gases include harmful carbon monoxide (co), which is colorless and

odorless. Observe the following precautions.

Failure to do so may cause exhaust gases enter the vehicle and may lead to

an accident c ...

If you have a flat tire

Your vehicle is equipped with a spare tire. The flat tire can be

replaced with the spare tire.

WARNING

â– If you have a flat tire

Do not continue driving with a flat tire.

Driving even a short distance with a flat tire can damage the tire and the

wheel beyond repair, which could result in an accide ...

Engine compartment

Engine coolant reservoir

Engine oil filler cap

Battery

Brake fluid reservoir

Fuse box

Radiator

Condenser

Electric cooling fans

Engine oil level dipstick

Washer fluid tank

Engine oil

With the engine at operating temperature and turned off, check the oil

level on the dips ...