Toyota RAV4 (XA40) 2013-2018 Service Manual: Reassembly

- Install wiring harness clamp bracket

- Install the bracket with the bolt.

- Install elbow tube

- Install straight pin

- Using a plastic hammer, install the 4 straight pins to the rear differential carrier.

- Thoroughly clean oil and water from the surface of the rear differential case that will face the differential ring gear.

- Install differential breather plug oil deflector

- Using a 5 mm socket hexagon wrench, install the rear differential breather plug oil deflector with the 2 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*Lbf)

Notice:

Install it so that the arrow mark faces the front (transmission coupling side) of the vehicle.

- Install differential ring gear

- Align the matchmarks on the rear differential case and differential ring gear, and install the differential ring gear.

- Install 10 new differential case bolts.

Torque: 90 n*m (918 kgf*cm, 66 ft.*Lbf)

Notice:

- The new bolts are coated with heat resistant oil. Do not wash it off.

- Install the rear differential case bolts by tightening diametrically opposite bolts uniformly in several passes.

- Install differential case bearing

- Using sst and a press, press-fit the rear differential case bearing rh (inner race) to the rear differential case.

Sst 09223-50010

Notice:

If the rear differential case bearing inner race is damaged, replace it with a new one.

- Using sst and a press, press-fit the rear differential case bearing lh (inner race) to the rear differential case.

Sst 09223-50010

Notice:

If the rear differential case bearing inner race is damaged, replace it with a new one.

- Install differential case bearing

- Using sst and a press, press-fit the rear differential side gear shaft washer and rear differential case bearing lh (outer race) to the differential side bearing retainer.

Sst 09950-60010 (09951-00510, 09951-00620, 09952-06010), 09950-70010 (09951-07150)

Notice:

- Install each rear differential side gear shaft washer to the place it was removed from.

- When replacing a bearing, replace the inner and outer races as a set.

- Install the rear differential side gear shaft oil seal after performing the teeth contact inspection and backlash adjustment.

- Using sst and a press, press-fit the rear differential side gear shaft washer and rear differential case bearing rh (outer race) to the rear differential carrier.

Sst 09950-60010 (09951-00510, 09951-00620, 09952-06010), 09950-70010 (09951-07150)

Notice:

- Install each rear differential side gear shaft washer to the place it was removed from.

- When replacing a bearing, replace the inner and outer races as a set.

- Install the rear differential side gear shaft oil seal after performing the teeth contact inspection and backlash adjustment.

- Install rear drive pinion front tapered roller bearing

- Using sst and a press, press-fit the rear drive pinion tapered roller bearing front (outer race) to the rear differential carrier.

Sst 09950-60010 (09951-00550), 09950-60020 (09951-00680), 09950-70010 (09951-07100)

- Install rear drive pinion rear tapered roller bearing

- Using sst, bolts, nuts and washers, install the rear drive pinion tapered roller bearing rear (outer race) to the rear differential carrier.

Sst 09950-60010 (09951-00600), 09950-60020 (09951-00680, 09951-00750)

Hint:

Use m12 x p1.25 Bolts with shaft lengths of 186 mm (part no. 90101-12159) And m12 x p1.25 Nuts (part no. 90179-12051) For the installation.

- Install rear drive pinion rear tapered roller bearing

- Install the rear differential drive pinion washer to the differential drive pinion.

Notice:

Install each rear differential drive pinion washer to the place it was removed from.

- Using sst and a press, press-fit the tapered roller rear (inner race) to the differential drive pinion.

Sst 09506-30012

- Adjust differential drive pinion preload

- Install the differential drive pinion (with rear drive pinion tapered roller bearing rear inner race) to the rear differential carrier.

- Install the rear drive pinion tapered roller bearing front inner race and a new rear drive pinion nut to the differential drive pinion.

Notice:

- New bearings are coated with anti-rust oil. If using new bearings, do not wash it off.

- If reusing a bearing, coat it with hypoid gear oil sx.

- Using sst, tighten a new rear drive pinion nut a little at a time until the specified preload is reached. Do not exceed the torque limit shown below.

Sst 09556-16011, 09564-16020

Torque: 245 n*m (2,500 kgf*cm, 181 ft.*Lbf) for use without sst

223 N*m (2,273 kgf*cm, 164 in.*Lbf) for use with sst

Hint:

Use a torque wrench with a fulcrum length of 30 cm (11.81 In.)

- Using sst and a torque wrench, measure the starting torque of the differential drive pinion.

Sst 09556-16011

Standard drive pinion preload (start torque)

Notice:

- For a more accurate measurement, rotate the bearing forward and backward before inspecting.

- Record the preload measurement for use with the total preload inspection.

- Install differential case

- Install the rear differential case to the rear differential carrier.

- Install differential side bearing retainer

- Using a scraper and wire brush, clean the seal packing from the rear differential carrier and differential side bearing retainer.

Notice:

Do not scratch the installation area.

- Install the differential side bearing retainer to the

rear differential carrier with the 8 bolts.

Torque: 34 n*m (350 kgf*cm, 25 ft.*Lbf)

- Adjust differential ring gear backlash

- Insert a dial gauge through the rear differential carrier cover plug hole, and set it perpendicular to the ring gear tooth surface's tip

- Using sst, fix the drive pinion in place.

Sst 09556-16011

- Using sst, rotate the rear differential case forward and backward, and measure the backlash.

Sst 09564-16020

Notice:

Measure at 3 or more areas around the circumference of the ring gear.

- If the result is not within the specified range, select washers that are thicker or thinner as necessary, where the thickness for the left and right side is the same. Then perform the rear differential case bearing outer race installation.

Hint:

- If the backlash is small, select a thick washer for the rh side and a thin washer for the lh side.

- If the backlash is large, select a thin washer for the rh side and a thick washer for the lh side.

- Inspect tooth contact between ring gear and drive pinion

- Remove the 8 bolts and differential side bearing retainer from the rear differential carrier.

- Remove the rear differential carrier case.

- Uniformly apply a light coat of prussian blue on both sides of the differential ring gear teeth.

- Install the rear differential case.

- Temporarily install the differential side bearing retainer to the differential carrier with the 8 bolts.

- Rotate the differential side pinion several times.

- Remove the 8 bolts and rear differential side bearing retainer from the differential carrier.

- Check the tooth contact pattern of the differential drive pinion and differential ring gear.

Notice:

Check the tooth contact pattern at 2 or more positions around circumference of the differential ring gear.

- Perform the following procedures for face or flank contact.

- Select washers that are thicker or thinner as necessary, where the thickness for the left and right side is the same. Then install the rear differential case bearing outer race.(*1)

- Repeat the differential ring gear and differential drive pinion tooth contact pattern inspection.

Hint:

If the tooth contact pattern is not correct, repeat*1.

- Repeat the differential ring gear and differential drive pinion backlash inspection.

Hint:

If the differential ring gear and differential drive pinion backlash is not as specified, replace the differential ring gear and differential drive pinion with new ones.

- Perform the following procedures for heel or toe contact.

- Select a drive pinion washer again and perform the rear drive pinion tapered roller bearing rear installation.

- Inspect total preload

- Using sst and a torque wrench, measure the starting torque with the teeth of the differential drive pinion and differential ring gear in contact.

Sst 09556-16011

Standard total preload:

standard drive pinion preload plus

Notice:

For a more accurate measurement, rotate the case bearing forward and backward before measuring.

- If the results are not within the specification, perform the procedures below.

- Select a side gear shaft washer for the rh side again, and then perform the rear differential case bearing outer race installation (rh side only).

- Repeat the total preload inspection.

- Repeat the ring gear backlash inspection.

- Repeat the differential ring gear and drive pinion tooth contact pattern inspection.

- Remove differential side bearing retainer

- Remove the 8 bolts and differential side bearing retainer from the rear differential carrier.

- Remove differential case

- Remove the rear differential case from the rear differential carrier.

- Remove differential drive pinion

- Install differential drive pinion bearing spacer

- Install a new rear differential drive pinion bearing spacer to the differential drive pinion.

- Install differential drive pinion

- Install the differential drive pinion to the rear differential carrier.

- Install rear drive pinion nut

- Apply hypoid gear oil lsd to the threads of the rear drive pinion nut.

- Install a new rear drive pinion nut to the differential drive pinion. Using sst, tighten the nut while confirming the preload.

Sst 09556-16011, 09564-16020

Sst 09564-16020

Torque: 245 n*m (2,500 kgf*cm, 181 ft.*Lbf) for use without sst 223 n*m (2,273 kgf*cm, 164 ft.*Lbf) for use with sst

Hint:

Use a torque wrench with a fulcrum length of 30 cm (11.81 In.).

- Adjust differential drive pinion preload

- Using sst and a torque wrench, inspect the starting torque.

Sst 09556-16011

Standard drive pinion preload

Notice:

- For a more accurate measurement, rotate the bearing forward and backward before adjusting.

- Adjust it so that it matches the drive pinion temporary adjustment starting torque.

- If the preload is insufficient, use sst to tighten the drive pinion nut 5 to 10Đ at a time. Measure the starting torque and repeat the adjustment as necessary until the preload matches the specified torque.

Sst 09564-16020

- If the tightening torque of the rear drive pinion nut

exceeds 245 n*m { 2500 kgf*cm } but the preload is

still insufficient, loosen the rear drive pinion nut.

Then check if the rear drive pinion nut and differential drive pinion screw threads are damaged.

- If there is no defect, replace the rear drive differential drive pinion bearing spacer, apply hypoid gear oil lsd to its threads and repeat the procedure above.

- Install differential case

- Install differential side bearing retainer

- Install the differential side bearing retainer to the

rear differential carrier with the 8 bolts.

Torque: 34 n*m (350 kgf*cm, 25 ft.*Lbf)

- Inspect differential ring gear backlash

- Inspect total preload

- Using sst and a torque wrench, measure the starting torque with the teeth of the differential drive pinion and differential ring gear in contact.

Sst 09556-16011

Standard total preload:

standard drive pinion preload plus

Notice:

For a more accurate measurement, rotate the case bearing forward and backward before measuring.

- If the results are not within the specified range, select a rear differential side gear shaft washer for the rh side again, and then perform the rear differential case bearing outer race installation (rh side only).

Notice:

If using a different rear differential side gear shaft washer, adjust the ring gear backlash.

Then adjust the total preload.

- Remove differential side bearing retainer

- Remove the 8 bolts and side bearing retainer from the rear differential carrier.

- Install differential side bearing retainer

- Using white gasoline, remove grease and oil from the alignment surfaces of the rear differential carrier and differential side bearing retainer.

- Apply seal packing to the areas indicated in the illustration of the differential side bearing retainer.

Seal packing: toyota genuine seal packing 1281, three bond 1281 or equivalent

Notice:

- Apply seal packing in a continuous line 2 to 3 mm (0.08 To 0.12 In.) In diameter.

- Perform the installation with 3 minutes of applying seal packing.

- Install the differential side bearing retainer to the rear differential carrier with the 8 bolts.

Torque: 34 n*m (350 kgf*cm, 25 ft.*Lbf)

Notice:

After installing the cover, do not add oil or drive the vehicle, and leave it alone for 1 hour or more. Also, avoid sudden acceleration and deceleration for 12 hours or more.

- Inspect total preload

- Using sst and a torque wrench, inspect the starting torque with the teeth of the differential drive pinion and differential ring gear in contact.

Sst 09556-16011 standard total preload:

Standard drive pinion preload plus

Notice:

For a more accurate measurement, rotate the case bearing forward and backward before inspecting.

- Inspect differential ring gear backlash

- Insert a dial gauge through the rear differential carrier cover plug hole, and set it perpendicular to the ring gear tooth surface's tip.

- Using sst, fix the drive pinion in place.

Sst 09556-16011

- Using sst, rotate the rear differential case forward and backward, and inspect the backlash.

Sst 09564-16020 standard backlash:

0.09 To 0.16 Mm (0.0004 To 0.006 In.)

Notice:

Inspect at 3 or more areas around the circumference of the ring gear.

- Install rear drive pinion nut

- Using a chisel and hammer, stake the rear drive pinion nut.

- Install diaphragm oil seal

- Apply a light coat of mp grease no. 2 To the lip of a new diaphragm oil seal.

- Using sst and a hammer, tap the diaphragm oil seal into the rear differential carrier according to the specification.

Sst 09710-30021 (09710-03121), 09950-60010 (09951-00570), 09950-70010 (09951-07100)

Standard distance: 7.0 +-0.5 Mm (0.28 +-0.02 In.)

- Install differential side gear shaft oil seal

- Apply a light coat of mp grease no. 2 To the lip of a new rear differential side gear shaft oil seal.

- Using sst and a hammer, tap the 2 rear differential side gear shaft oil seals into the rear differential carrier and differential side bearing retainer according to the specification.

Sst 09223-00010

Standard distance: 7.2 +-0.5 Mm (0.28 +-0.02 In.)

- Install transmission coupling shim

- Measure each of the dimensions.

Hint:

- Dimension a: bearing axis distance

- Dimension b: drive pinion axis distance

- Select a transmission coupling shim based on the difference between dimensions a and b, and install the shim.

- Remove transmission coupling conical spring washer

- Install the transmission coupling conical spring washer to the rear differential carrier.

Notice:

Install the transmission coupling conical spring washer so that the green marking (protruding part) is facing the front of the vehicle (coupling side).

- Install yoke

- Using a 5 mm socket hexagon wrench, install the

yoke with the 3 bolt.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*Lbf)

- Install 4wd linear solenoid

- Install a new o-ring to the solenoid.

Notice:

Do not damage or twist the o-ring.

- Install the solenoid to the yoke.

- Install the snap ring.

- Install electromagnetic coupling

- Using white gasoline, remove grease and oil from the alignment surfaces of the rear differential carrier and transmission coupling.

- Apply seal packing 1281 to the areas indicated in the illustration of the transmission coupling.

Seal packing: toyota genuine seal packing 1281, three bond 1281 or equivalent

Notice:

- Apply seal packing 1281 in a continuous line 2 to 3 mm (0.08 To 0.12 In.) In diameter.

- Perform the installation with 3 minutes of applying seal packing 1281.

- Install the rear differential carrier cover to the rear

differential carrier assembly with the 4 bolts.

Torque: 19.6 N*m (200 kgf*cm, 14 ft.*Lbf)

- Install differential carrier cover breather plug

- Using a plastic-faced hammer, tap in the breather plug.

Sst 09612-07010 (09612-10061)

- Install differential carrier cover plug

- Using an 8 mm socket hexagon wrench, install a new rear differential carrier cover plug.

Torque: 30 n*m (306 kgf*cm, 22 ft.*Lbf)

- Install differential filler plug

- Install a new gasket to the rear differential filler plug.

- Using a 10 mm socket hexagon wrench, install the rear differential filler plug.

Torque: 39 n*m (400 kgf*cm, 29 ft.*Lbf)

- Install differential drain plug

- Install a new gasket to the rear differential drain plug.

- Using a 10 mm socket hexagon wrench, install the rear differential drain plug.

Torque: 39 n*m (400 kgf*cm, 29 ft.*Lbf)

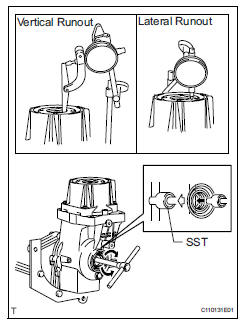

- Inspect runout of transmission coupling assembly

- Install a dial gauge so that it is perpendicular to the inner side of the transmission coupling.

- Using sst, rotate the transmission coupling forward and backward and measure the vertical runout.

Sst 09564-16020

Maximum vertical runout: 0.06 Mm (0.0024 In.)

- Install a dial gauge perpendicularly onto the transmission coupling, as shown in the illustration.

- Using sst, rotate the transmission coupling forward and backward and measure the lateral runout.

Sst 09564-16020

Maximum lateral runout: 0.07 Mm (0.0028 In.)

- Install stud bolt

- Install the differential support assembly rear with the 4 bolts.

Torque: 8 n*m (82 kgf*cm, 71 in.*Lbf)

Disassembly

Disassembly

Fix differential carrier sub-assembly

Fix the rear differential carrier in place with the

overhaul attachment.

Remove stud bolt

Remove the 4 stud bolts from the transmission

c ...

Installation

Installation

Install rear differential support

Install the differential support to the differential

carrier with the 4 bolts.

Torque: 98 n*m (999 kgf*cm, 72 ft.*Lbf)

Install rear differential ...

Other materials:

Fail-safe chart

Fail-safe function

When communication fails in any of the main wires

(communication lines) due to a short circuit or other

causes, the fail-safe function, which is specified for

each system, operates to prevent the system from

malfunctioning.

The table below shows the effects on e ...

Sun visors and vanity

mirrors

Sun visors

Forward position:

flip down.

Side position:

flip down, unhook, and swing

to the side.

Side extender (if equipped):

place in side position then slide

backwards.

Vanity mirrors

Slide the cover to open.

The light turns on when the cover

is opened.

Notice

To ...

Power steering ecu communication stop mode

Description

Wiring diagram

Inspection procedure

Notice:

Turn the ignition switch off before measuring the resistances of the

main wire and the branch

wire.

After the ignition switch is turned off, check that the key reminder

warning system and light

reminder warning system ...