Toyota RAV4 (XA40) 2013-2018 Service Manual: Installation (2006/01- )

- Install front drive shaft assembly lh

- Coat the spline of the inboard joint shaft with gear oil.

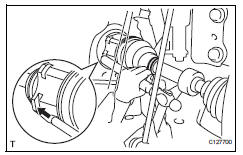

- Align the shaft splines and tap in the drive shaft with a brass bar and hammer.

Notice:

- Set the snap ring with the opening side facing downwards.

- Be careful not to damage the oil seal, boot and dust cover.

- Install front drive shaft assembly rh

- Coat the spline of the inboard joint shaft with gear oil.

- Align the shaft splines and securely insert the drive shaft.

- Install the 2 bearing bracket bolts.

Torque: 63.7 N*m (650 kgf*cm, 47 ft.*Lbf)

Notice:

Do not damage the oil seal, boot and dust cover.

- Connect steering knuckle with axle hub lh

- Align the shaft splines in the drive shaft to the steering knuckle with axle hub, and connect the steering knuckle with axle hub.

- Connect steering knuckle with axle hub rh

Hint:

Use the same procedures described for the lh side.

- Connect front suspension no. 1 Lower arm sub-assembly lh (see page sp-24)

- Connect front suspension no. 1 Lower arm sub-assembly rh

Hint:

Use the same procedures described for the lh side.

- Install front stabilizer link assembly lh (see page sp-31)

- Install front stabilizer link assembly rh

Hint:

Use the same procedures described for the lh side.

- Connect tie rod end sub-assembly lh (see page ps-45)

- Connect tie rod end sub-assembly rh

Hint:

Use the same procedures described for the lh side.

- Connect front speed sensor lh

- Connect the speed sensor (see page bc-193).

- Install front speed sensor rh

Hint:

Use the same procedures described for the lh side.

- Install front axle hub nut (see page ah-11)

- Install front wheel torque: 103 n*m (1,050 kgf*cm, 76 ft.*Lbf)

- Add automatic transaxle fluid

- Add automatic transaxle fluid for u140f (see page ax-152).

- Add automatic transaxle fluid for u241e (see page ax-151).

- Add automatic transaxle fluid for u151e (see page ax-177).

- Check for automatic transaxle oil leakage

- Inspect and adjust front wheel alignment

- Inspect and adjust the front wheel alignment (see page sp-3).

Installation (2005/11-2006/01)

Installation (2005/11-2006/01)

Install front drive shaft assembly lh

Coat the spline of the inboard joint shaft with gear

oil.

Using a brass bar and hammer, align the shaft

splines in the drive shaft.

Notice:

...

Front drive shaft assembly (for 4wd)

Front drive shaft assembly (for 4wd)

Components (2005/11-2006/01)

Components (2006/01- )

...

Other materials:

Pressure sensor circuit

Description

This dtc is output when the refrigerant pressure is either extremely low

(0.19 Mpa [2.0 Kgf/cm2, 28 psi]

or less) or extremely high (3.14 Mpa [32.0 Kgf/cm2, 455 psi] or more). The air

conditioning pressure

sensor, which is installed on the pipe of the high pressure side, detec ...

Front wiper rubber

Components

Removal

Remove front wiper blade

Detach the claw as shown in the illustration.

Remove the wiper blade as shown in the illustration.

Notice:

Do not fold the wiper arm with the wiper blade

removed. The arm tip may damage the

windshield surface.

Rem ...

Installation

Install knock sensor

Install the sensor with the nut.

Torque: 20 n*m (205 kgf*cm, 15 ft.*Lbf)

Notice:

Make sure that the knock sensor is in the

correct position.

Connect the sensor connector.

Install intake manifold insulator

install the intake manifold insulat ...