Toyota RAV4 (XA40) 2013-2018 Service Manual: Installation

- Install drive plate sub-assembly

- Clean the 8 bolts and 8 bolt holes.

- Apply adhesive to 2 or 3 threads of the 8 bolts.

Adhesive:

Toyota genuine adhesive 1342, three bond 1342 or equivalent

- Using sst, hold the crankshaft.

Sst 09213-54015 (91651-60855), 09330-00021

- Install the front spacer.

Hint:

Align the pin of the front spacer with the pin hole of the crankshaft.

- Install the drive plate and rear spacer onto the crankshaft.

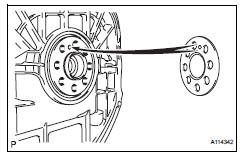

- Using several steps, uniformly install and tighten the

8 bolts in the sequence shown in the illustration.

Torque: 98 n*m (1,000 kgf*cm, 72 ft.*Lbf)

- Install torque converter clutch assembly

- Install the torque converter clutch for u241e (2wd) (see page ax-148).

- Install the torque converter clutch for u140f (4wd) (see page ax-149).

- Install automatic transaxle assembly

- Install the automatic transaxle for u241e (2wd) (see page ax-149).

- Install the automatic transaxle for u140f (4wd) (see page ax-150).

- Install starter assembly (see page st-14)

- Install transfer assembly (for 4wd) (see page tf-75)

- Install drive shaft bearing bracket (for 2wd)

- Install the bracket with the 3 bolts.

Torque: 64 n*m (653 kgf*cm, 47 ft.*Lbf)

- Install drive shaft bearing bracket (for 4wd)

- Install the bracket with the 3 bolts.

Torque: 64 n*m (653 kgf*cm, 47 ft.*Lbf)

- Install engine hanger

- Install the no. 1 And no. 2 Engine hangers.

Torque: 38 n*m (387 kgf*cm, 28 ft.*Lbf)

part no.

- Attach the sling device and the engine with the chain block.

- Install engine assembly with transaxle

- Lift the engine assembly (with transaxle) with the chain block.

- Lower the engine out of the vehicle slowly and carefully.

Notice:

Make sure the engine is clear of all wiring, hoses and cables.

- Install engine mounting insulator lh

- Install the engine mounting insulator lh with the 4 bolts.

Torque: 95 n*m (969 kgf*cm, 70 ft.*Lbf)

- Install the engine mounting insulator lh with the through bolt and nut.

Hint:

Install the through bolt by tightening the nut.

Torque: 56 n*m (571 kgf*cm, 41 ft.*Lbf)

- Install engine mounting insulator rh

- Install the engine mounting insulator rh with the 2 bolts and 2 nuts.

Torque: 95 n*m (969 kgf*cm, 70 ft.*Lbf) for bolt

95 N*m (969 kgf*cm, 70 ft.*Lbf) for nut a

52 N*m (530 kgf*cm, 38 ft.*Lbf) for nut b

- Remove engine hanger

- Remove the no. 1 And no. 2 Engine hangers.

- Install engine mounting insulator rr

- Install the engine mounting insulator rr with the 2 nuts and 2 bolts.

Torque: 95 n*m (969 kgf*cm, 70 ft.*Lbf)

- Install the through bolt which is used to secure the rear engine mounting insulator, into the rear engine mounting bracket.

Torque: 95 n*m (969 kgf*cm, 70 ft.*Lbf)

- Install engine mounting insulator fr

- Install the engine mounting insulator fr with the 2 bolts.

Torque: 95 n*m (969 kgf*cm, 70 ft.*Lbf)

- Install the through bolt and nut which is used to secure the front engine mounting bracket fr.

Hint:

Install the through bolt by tightening the nut.

Torque: 145 n*m (1,479 kgf*cm, 107 ft.*Lbf)

- Install propeller shaft assembly (for 4wd)

- Install the propeller shaft (see page pr-5).

- Install front drive shaft assembly

- Install the front drive shaft rh (for 2wd) (see page ds-32).

- Install the front drive shaft rh (for 4wd) (see page ds-65).

- Install front exhaust pipe (see page ex-4)

- Connect engine wire

- Install the ground cable with the bolt located near the starter.

Torque: 13 n*m (133 kgf*cm, 10 ft.*Lbf)

- Connect the ground cable to the clamp located near the starter.

- Connect the engine wire to the positive (+) battery terminal with the nut.

Torque: 13 n*m (133 kgf*cm, 10 ft.*Lbf)

- Connect the ground cable connector.

- Connect the 2 engine wire connectors and install the nut.

- Install the engine room relay block cover.

- Attach the clamp of the engine wire cover.

- Install the engine wire cover to with the bolt.

- Install ecm (see page es-430)

- Install cooler compressor assembly (see page ac-217)

- Install generator assembly (see page ch-15)

- Install fan and generator v belt (see page em-7)

- Install front suspension member reinforcement rh (see page em-7)

- Install transaxle control cable assembly

- Install the transaxle control cable for u241e (see page ax-130).

- Install the transaxle control cable for u140f (see page ax-130).

- Install intake manifold insulator (see page es-421)

- Install intake manifold (see page es-421)

- Install fuel delivery pipe sub-assembly (see page fu-13)

- Connect no. 2 Ventilation hose (see page fu- 14)

- Install throttle body assembly (see page es-413)

- Connect fuel tube (see page fu-14)

- Connect heater water outlet hose

- Connect the heater water outlet hose to the air conditioner tube.

- Connect heater water inlet hose

- Connect the heater water inlet hose to the air conditioner tube.

- Connect union to connector tube hose

- Connect the 2 union to connector tube hoses to the booster vacuum tube.

- Install battery carrier bracket

- Install the battery carrier bracket with the nut and 2 bolts.

Torque: 20 n*m (204 kgf*cm, 15 ft.*Lbf)

- Install battery bracket reinforcement

- Install the battery bracket reinforcement with the 2 bolts.

Torque: 20 n*m (204 kgf*cm, 15 ft.*Lbf)

- Install front battery carrier

- Install the front battery carrier with the 4 bolts.

Torque: 20 n*m (204 kgf*cm, 15 ft.*Lbf)

- Connect the 2 clamps of the engine wire.

- Install air cleaner case sub-assembly

- Connect the air cleaner case to the no. 1 Air cleaner inlet.

- Install the air cleaner case with the 3 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*Lbf)

- Install air cleaner filter element subassembly

- Install air cleaner cap (see page es-413)

- Install purge vsv (see page ec-16)

- Install radiator reservoir

- Install the reservoir with the 2 bolts.

Torque: 5.0 N*m (51 kgf*cm, 44 in.*Lbf)

- Install radiator assembly

- Install the radiator (see page co-32).

- Install battery tray

- Install battery

- Install the battery.

- Install the battery clamp with the bolt and nut.

Torque: 8.5 N*m (87 kgf*cm, 75 in.*Lbf) for bolt

5.0 N*m (51 kgf*cm, 44 in.*Lbf) for nut

- Connect cable to negative battery terminal

- Add automatic transaxle fluid

- Add automatic transaxle fluid for u241e (2wd) (see page ax-151).

- Add automatic transaxle fluid for u140f (4wd) (see page ax-152).

- Check for fuel leaks (see page fu-14)

- Add engine coolant (see page co-6)

- Check for engine coolant leaks (a) check for engine coolant leaks (see page co-1).

- Check for automatic transaxle fluid leaks

- Adjust shift lever position

- Adjust the shift lever position for u241e (2wd) (see page ax-138).

- Adjust the shift lever position for u140f (4wd) (see page ax-138).

- Install no. 1 Engine cover (see page em-43)

- Install front fender apron rh

- Install no. 2 Engine under cover

- Install no. 1 Engine under cover

- Install front wheel

- Install radiator support opening cover

- Install hood sub-assembly

- Install the hood (see page ed-7).

- Adjust the hood (see page ed-5).

- Inspect and adjust front wheel alignment

- Inspect and adjust the front wheel alignment (see page sp-3).

- Perform registration

- When replacing the engine assembly, perform vehicle stability control system recognition in ecm (see page cc-12).

- Reset memory (for automatic transaxle)

- When replacing the engine assembly, perform the reset memory procedure (a/t initialization) for u241e (2wd) (see page ax-18) and for u140f (4wd) (see page ax-18).

Removal

Removal

Discharge fuel system pressure (see page

fu-9)

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) batte ...

Engine unit

Engine unit

...

Other materials:

Installation

Install no. 2 Chain sub-assembly

Set the crankshaft key in the left horizontal position.

Turn the cutout of the drive shaft so that it faces

upward.

Align the yellow mark links with the timing marks of

each gear as shown in the illustration.

Install the sprockets onto ...

Transmission fluid temperature sensor "A" circuit

Description

The automatic transmission fluid (atf) temperature sensor converts the atf

temperature into a

resistance value which is input into the ecm.

The ecm applies a voltage to the temperature sensor through ecm terminal tho1.

The sensor resistance changes with the atf temperature. ...

Freeze frame data

Freeze frame data

Hint:

Whenever a dtc is detected or the abs operates,

the skid control ecu stores the current vehicle

(sensor) state as freeze frame data.

The skid control ecu stores the number of times

(maximum: 31) the ignition switch has been turned

from off to on since the ...