Toyota RAV4 (XA40) 2013-2018 Service Manual: Evaporative emission leak detection pump

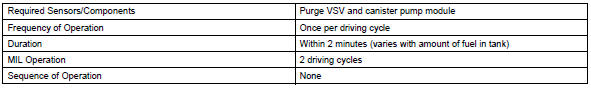

Dtc summary

Hint:

The leak detection pump is built into the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

Monitor description

5 Hours* after the ignition switch is turned off, the leak detection pump creates negative pressure (vacuum) in the evap system. The ecm monitors for leaks and actuator malfunctions based on the evap pressure.

Hint:

*: If the engine coolant temperature is not below 35°c (95°f) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35°c (95°f) 7 hours after the ignition switch is turned to off, the monitor check starts 2.5 Hours later.

![]()

*: If only a small amount of fuel is in the fuel tank, it takes longer for the evap pressure to stabilize.

- P2401: leak detection pump stuck off in operation b, the leak detection pump creates negative pressure (a vacuum) through the reference orifice. The evap system pressure is then measured by the ecm, using the canister pressure sensor, to determine the reference pressure. If the pressure is higher than -1.057 Kpa-g (-7.93 Mmhg-g), or lower than -4.85 Kpa-g (-36.4 Mmhg-g), the ecm interprets this as the leak detection pump being stuck off (not operating). The ecm illuminates the mil and sets the dtc (2 trip detection logic).

- P2402: leak detection pump stuck on in operation b, the leak detection pump creates negative pressure (a vacuum) through the reference orifice. The evap (evaporative emission) system pressure is then measured by the ecm, using the canister pressure sensor, to determine the reference pressure. If the pressure is higher than -1.057 Kpa-g (-7.93 Mmhg-g), or lower than -4.85 Kpa-g (-36.4 Mmhg-g), the ecm interprets this as the leak detection pump being stuck on (remaining on all the time). The ecm illuminates the mil and sets the dtc (2 trip detection logic).

Hint:

The detection logic of dtcs p2401 and p2402 is the same because in both cases the reference pressure measured in operation b is compared to the atmospheric pressure registered in operation a.

The ecm calculates the difference between these pressures by deducting [the reference pressure] from [the stored atmospheric pressure], and uses this to monitor the evap system pressure change.

Monitor strategy

Typical enabling conditions

Typical malfunction thresholds

"Saturated" indicates that the evap pressure change is less than 0.286 Kpa-g (2.14 Mmhg-g) in 60 seconds.

Monitor result

Refer to checking monitor status (see page es-17).

Oxygen (a/f) sensor pumping current circuit

Oxygen (a/f) sensor pumping current circuit

Description

Refer to dtc p2195 (see page es-292).

Monitor description

The air-fuel ratio (a/f) sensor varies its output voltage in proportion to

the air-fuel ratio. If the a/f sensor

imp ...

Evaporative emission system switching valve control

Evaporative emission system switching valve control

Dtc summary

Hint:

The vent valve is built into the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see

page es-335).

Inspection ...

Other materials:

Multi-information display

Display contents

The multi-information display presents the driver with a variety of driving-

related data including the current outside air temperature.

Outside temperature display

Indicates the outside temperature.

The temperature range that can be

displayed is from -40„af (-40„ac) t ...

Short in driver side squib 2nd step circuit

Description

The driver side squib 2nd step circuit consists of the center airbag sensor,

the spiral cable and the

steering pad.

The circuit instructs the srs to deploy when the deployment conditions are met.

These dtcs are recorded when a malfunction is detected in the driver side squi ...

Steering column assembly

Components

Removal

Caution:

Some of these service operations affect the srs airbag

system. Read the precautionary notices concerning the

srs airbag system before servicing the steering column

(see page rs-1).

Place front wheels facing straight ahead

Disconnect cab ...