Toyota RAV4 (XA40) 2013-2018 Service Manual: Canister

Components

removal

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

- Remove canister

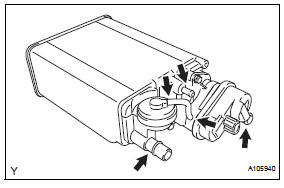

- Disconnect the 2 tubes, hose and connector.

- Using a screwdriver, pry up the retainer.

Hint:

Do not remove the retainer.

- Disconnect the purge line hose.

- Disconnect the air inlet line tube from the canister.

- Disconnect the vent line tube from the canister (leak detection pump).

- Disconnect the connector from the canister (leak detection pump).

Notice:

Remove any dirt or foreign objects on the fuel tube connector before performing this work.

- Do not allow any scratches or foreign objects on the parts when disconnecting as the fuel tube connector has the o-ring that seals the pipe.

- Perform this work by hand. Do not use any tools.

- Do not forcibly bend, twist or turn the nylon tube.

- Protect the disconnected part by covering it with a plastic bag after disconnecting the fuel tank vent hose.

- If the fuel tube connector and pipe are stuck, push and pull to release them.

- Remove the 4 bolts, clip and canister.

Inspection

- Inspect canister

- Visually check the canister for cracks or damage.

If cracks or damage is found, replace the canister.

- While holding the purge port closed, blow air

0.39 Kpa (4.0 Kgf/cm2, 3 mmhg) into the vent

port, and check that air flows from the air inlet

port.

If the result is not as specified, replace the canister.

- While holding the air inlet port closed, blow air

0.39 Kpa (4.0 Kgf/cm2, 3 mmhg) into the vent

port, and check that air flows from the purge

port.

If the result is not as specified, replace the canister.

- While holding the air inlet port closed, apply

vacuum 3.43 Kpa (35.0 Kgf/cm2, 25.7 Mmhg)

to the vent port, and check that air is sucked

into the purge port.

If the result is not as specified, replace the canister.

- Check the air tightness.

- While holding the vent and air inlet ports

closed, apply vacuum 3.43 Kpa (35.0 Kgf/cm2,

25.7 Mmhg) to the purge port, and check that

the vacuum is maintained for 1 minute.

If the result is not as specified, replace the canister.

- Check the diaphragm.

- Remove the air hose between ports a and b.

- While holding the vent, purge and air inlet ports closed, apply vacuum 1.42 Kpa (14.5 Kgf/cm2, 10.6 Mmhg) to port a, and check that air is not sucked into port b.

- While holding the vent, purge and air inlet ports Closed, apply vacuum 1.42 Kpa (14.5 Kgf/cm2, 10.6 Mmhg) to port a, and measure how long it takes for the vacuum to drop.

Vacuum drop time: 10 seconds or more

If the result is not as specified, replace the canister.

- Check the leak detection pump.

- Check that air flows from port a to port b and

c.

If the result is not as specified, replace the canister.

- Connect the positive (+) lead of the battery to terminal 7 and the negative (-) lead to terminal 6.

- Check that the valve is closed.

If the result is not as specified, replace the canister.

- Install the canister pump module.

Installation

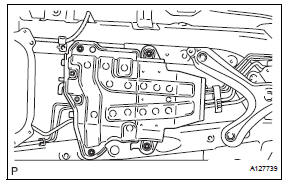

- Install canister

- install the canister with the 4 bolts and clip.

torque: 20 n*m (204 kgf*cm, 15 ft.*lbf)

- Connect the air inlet line tube to the canister (leak detection pump).

- Install the vent line tube.

- Connect the pipe to the fuel tube connector, as shown in a in the illustration. Then push up the retainer to lock the claws, as shown in b in the illustration.

Notice:

- Check that there are no scratches or foreign objects around the connected part of the fuel tube connector and pipe before performing this work.

- After connecting the fuel tank vent tube, check that the fuel tank vent tube is securely connected by pulling the fuel tube connector and pipe.

- Connect the purge line hose.

Hint:

Install the hose to the canister, and then attach the retainer.

- Connect the connector to the canister (leak detection pump).

- Connect cable to negative battery terminal

Emission control system

Emission control system

Parts location

System diagram

On-vehicle inspection

Check fuel cut rpm

Increase the engine speed to at least 3,500 rpm.

Use a sound scope to check for injecto ...

Vacuum switching valve

Vacuum switching valve

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent ai ...

Other materials:

Cruise control system cruise control main switch

Components

Removal

Caution:

Be sure to read the precautionary notices concerning the

srs airbag system before servicing it (see page rs-1).

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) batt ...

Oxygen (a/f) sensor signal stuck

Hint:

Although the dtc titles say oxygen sensor, these dtcs relate to the

air-fuel ratio (a/f) sensor.

Sensor 1 refers to the sensor mounted in front of the three-way

catalytic converter (twc) and

located near the engine assembly.

Description

The a/f sensor generates a voltage* ...

Utility vehicle

precautions

This vehicle belongs to the utility vehicle class, which has

higher ground clearance and narrower tread in relation to the

height of its center of gravity to make it capable of performing in

a wide variety of off-road applications.

Utility vehicle feature

Specific design characteristics give ...