Toyota RAV4 (XA40) 2013-2018 Service Manual: Wiper switch

Precaution

- Precaution for vehicle with srs

- Some procedures in this section may affect the supplemental restraint system (srs). Prior to performing the procedures, read the srs section's "precaution" (see page ss-2).

Components

Removal

- Disconnect cable from negative battery terminal

Caution:

Wait at least 90 seconds after disconnecting the cable from the negative (-) battery terminal to prevent airbag and seat belt pretensioner activation.

- Place front wheels facing straight ahead

- Remove steering pad assembly (see page rs- 336)

- Remove steering wheel assembly (see page sr-12)

- Remove steering column cover upper (see page sr-12)

- Remove steering column cover lower (see page sr-12)

- Remove wiper and washer switch assembly

- Disconnect the connectors.

- Detach the claw and remove the wiper switch.

Notice:

Do not push the claw with excessive force as damage may occur.

Inspection

- Inspect windshield wiper switch assembly

- Check the front wiper switch.

- Measure the resistance of the switch.

Standard resistance

If the result is not as specified, replace the switch assembly.

- Check the front washer switch assembly.

- Measure the resistance of the switch.

Standard resistance

If the result is not specified, replace the switch assembly.

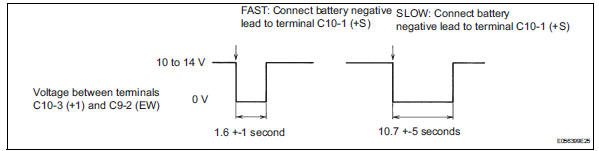

- Check the intermittent operation.

- Connect the voltmeter's positive (+) lead to terminal e10-3 (+1) and the negative (-) lead to terminal e9-2 (ew).

- Connect the battery's positive (+) lead to terminal e10-2 (+b) and the negative (-) lead to terminal e9-2 (ew) and e10-1 (+s).

- Turn the wiper switch to the int position.

- Connect the battery's positive (+) lead to terminal e10-1 (+s) for 5 seconds.

- Connect the battery's negative (-) lead to terminal e10-1 (+s). Operate the intermittent wiper relay and check the voltage between terminals e10-3 (+1) and e9-2 (ew).

Standard voltage: refer to the illustration below.

If the result is not as specified, replace the switch assembly.

- Check the front washer operation.

- Turn the wiper switch off.

- Connect the battery's positive (+) lead to terminal e10-2 (+b) and the negative (-) lead to terminals e10-4 (+s) and e9-2 (ew).

- Connect the voltmeter's positive (+) lead to e10-3 (+1) and the negative (-) lead to terminal e9-2 (ew).

- Turn the washer switch on and off, and check the voltage between terminals e10-3 (+1) and e9-2 (ew).

Ok: refer to the illustration below.

If the result is not as specified, replace the switch assembly.

- check the rear wiper switch.

- Measure the resistance of the switch.

Standard resistance

If the result is not as specified, replace the switch assembly.

- Check the rear washer switch.

- Measure the resistance of the switch.

Standard resistance

If the result is not as specified, replace the switch assembly.

Installation

- Install wiper and washer switch assembly

- Attach the claw to install the wiper switch.

- Connect the connectors.

Notice:

Do not push the claw with excessive force as damage may occur.

- Install steering column cover lower (see page sr-20)

- Install steering column cover upper (see page sr-20)

- Install steering wheel assembly (see page sr-21)

- Place front wheels facing straight ahead

- Inspect steering wheel center point

- Install steering pad assembly (see page rs- 336)

- Connect cable to negative battery terminal

- Inspect steering pad assembly (see page rs- 337)

- Check srs warning light

- Check the srs warning light (see page rs-337).

Rear wiper rubber

Rear wiper rubber

Components

Removal

Remove rear wiper blade assembly

Rotate and remove the cap as described in the

"remove" procedures.

Raise the arm and blade.

Raise the wip ...

Washer motor

Washer motor

Components

Removal

Disconnect cable from negative battery

terminal

Caution:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent ai ...

Other materials:

Using the steering wheel audio switches

Some audio features can be controlled using the switches on

the steering wheel.

Operation may differ depending on the type of audio system or

navigation system. For details, refer to the manual provided with

the audio system or navigation system.

Volume

Radio mode:

selects a radio stat ...

Inside rear view mirror

The rear view mirror’s position can be adjusted to enable sufficient

confirmation of the rear view.

Adjusting the height of rear view mirror

The height of the rear view mirror can be adjusted to suit your driving

posture.

Adjust the height of the rear view

mirror by moving it up and down.

...

Removal

(2005/11-2006/01)

Remove front wheel

Drain automatic transaxle fluid

Drain the automatic transaxle fluid for u140f (see

page ax-147).

Drain the automatic transaxle fluid for u241e (see

page ax-146).

Remove front axle hub nut (see page ah-6)

Disconnect front speed sensor lh (see page

bc-191) ...