Toyota RAV4 (XA40) 2013-2018 Service Manual: Oil pump

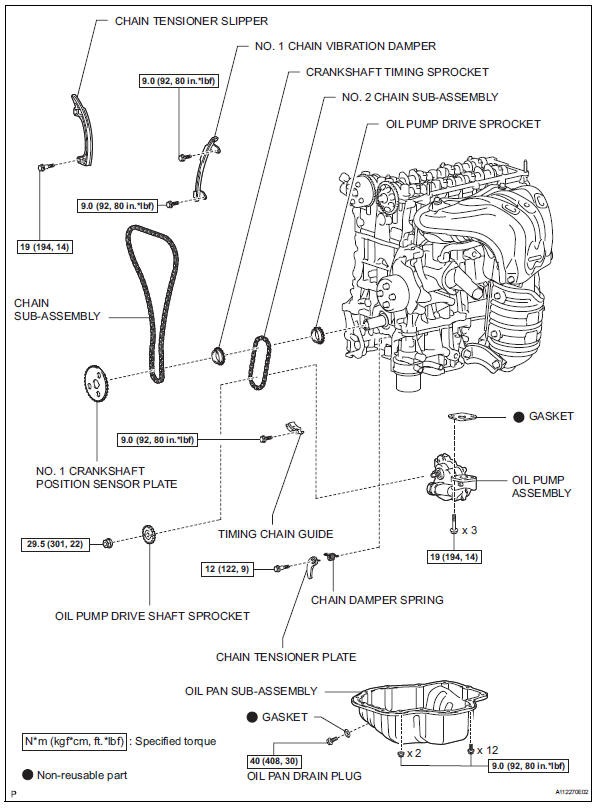

Components

Removal

- Remove chain sub-assembly

- Remove the chain (see page em-22).

- Remove oil pump assembly

- Remove the 3 bolts, oil pump and gasket.

Disassembly

- Remove oil pump strainer

- Remove the 2 nuts, oil pump strainer and gasket.

- Remove oil pump relief valve

- Using a 27 mm socket wrench, remove the plug.

- Remove the valve spring and relief valve.

- Remove oil pump cover

- Remove the 5 bolts and oil pump cover.

Inspection

- Inspect oil jet

- Check the oil jet for damage or clogging.

If necessary, repair the cylinder block.

- Inspect oil pump relief valve

- Check the relief valve.

- Coat the valve with engine oil, and then check

that the valve falls smoothly into the valve hole

by its own weight.

If it does not, replace the relief valve. If necessary, replace the oil pump assembly.

- Inspect oil pump rotor

- Check the side clearance.

- Using a feeler gauge and precision straightedge, measure the clearance between the rotors and precision straightedge.

Standard clearance: 0.030 To 0.085 Mm (0.0012 To 0.0033 In.)

Maximum clearance: 0.16 Mm (0.0063 In.)

If the side clearance is greater than the maximum, replace the oil pump assembly.

- Check the tip clearance.

- Using a feeler gauge, measure the clearance between the drive and driven rotor tips.

Standard clearance: 0.080 To 0.160 Mm (0.0031 To 0.0063 In.)

Maximum clearance: 0.35 Mm (0.0138 In.)

If the tip clearance is greater than the maximum, replace the oil pump assembly.

- Check the body clearance.

- Using a feeler gauge, measure the clearance between the driven rotor and pump body.

Standard clearance: 0.100 To 0.170 Mm (0.0039 To 0.0067 In.)

Maximum clearance: 0.325 Mm (0.01128 In.)

If the body clearance is greater than the maximum, replace the oil pump assembly.

- Inspect oil pump drive chain and 2 oil pump sprockets

- Using vernier calipers, measure the length of the 8 links with the chain fully stretched.

Maximum chain elongation: 52.4 Mm (2.063 In.)

If the elongation is greater than the maximum, replace the chain.

Hint:

Make the measurements at 3 or more places selected at random.

- Wrap the chain around the oil pump sprocket.

- Using vernier calipers, measure the sprocket diameter with the chain.

Notice:

Vernier calipers must contact the chain rollers when measuring.

Minimum sprocket diameter (with chain): crankshaft 48.2 Mm (1.898 In.) Oil pump drive shaft 48.2 Mm (1.898 In.)

If the diameter is less than the minimum, replace the chain and sprockets.

- Inspect chain tensioner plate

- Measure the chain tensioner plate wear.

Maximum wear: 0.5 Mm (0.020 In.)

If the wear is greater than the maximum, replace the chain tensioner plate.

Reassembly

- Install oil pump rotor

- Coat the drive rotor and driven rotor with engine oil.

- Place the drive and driven rotors into the oil pump with the marks facing the pump cover side.

- Install oil pump cover

- Install the oil pump cover with the 5 bolts.

Torque: 8.8 N*m (90 kgf*cm, 78 in.*Lbf)

- Install oil pump relief valve

- Coat the relief valve with engine oil.

- Insert the relief valve and spring into the pump body hole.

- Using a 27 mm socket wrench, install the plug.

Torque: 49 n*m (500 kgf*cm, 36 ft.*Lbf)

- Install oil pump strainer

- Install a new gasket and the oil strainer with the 2 nuts.

Torque: 8.8 N*m (90 kgf*cm, 78 in.*Lbf)

Installation

- Install oil pump assembly

- Install a new gasket and the oil pump with the 3 bolts.

Torque: 19 n*m (194 kgf*cm, 14 ft.*Lbf)

- Install chain sub-assembly

- Install the chain (see page em-32).

Oil filter

Oil filter

Components

Replacement

Caution:

Prolonged and repeated contact with engine oil will

cause the loss of natural oils from the skin, leading to

dryness, irritation and dermatitis. In additi ...

Brake

Brake

...

Other materials:

Oxygen sensor circuit

Description

In order to obtain a high purification rate of the carbon monoxide (co),

hydrocarbon (hc) and nitrogen

oxide (nox) components in the exhaust gas, a twc is used. For the most efficient

use of the twc, the

air-fuel ratio must be precisely controlled so that it is always close to ...

Suspension & axle front shock absorber with coil spring (for sport package)

Components

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Remove front wheel

Remove front speed sensor lh (see page bc-

191)

Remove front stabilizer link assembly lh

(see page sp-30)

Remove front shock a ...

Air mix damper control servo motor circuit (driver

side)

Description

The air mix damper servo sends pulse signals to indicate the damper position

to the air conditioning

amplifier. The air conditioning amplifier activates the motor (normal or

reverse) based on these signals to

move the air mix damper (driver seat) to the appropriate position. T ...