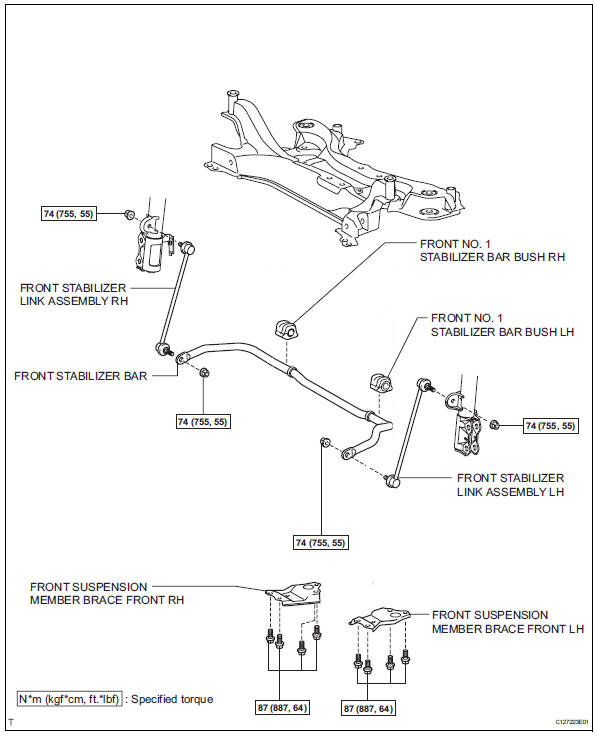

Toyota RAV4 (XA40) 2013-2018 Service Manual: Front stabilizer bar

Components

Removal

- Remove front wheel

- Remove front stabilizer link assembly lh

- Remove the 2 nuts and stabilizer link.

- Remove front stabilizer link assembly rh

Hint:

Use the same procedures described for the lh side.

- Remove front suspension member brace front lh

- Remove the 4 bolts and member brace from the corssmember.

- Remove front suspension member brace front rh

Hint:

Use the same procedures described for the lh side.

- Remove front stabilizer bar

- Remove the stabilizer bar from the crossmember.

- Remove front no. 1 Stabilizer bar bush lh

- Remove the bush from the stabilizer bar.

- Remove front no. 1 Stabilizer bar bush rh

Hint

Use the same procedures described for the lh side.

Inspection

- Inspect front stabilizer link assembly lh

- As shown in the illustration, move the ball joint stud back and forth 5 times before installing the nut.

- Using a torque wrench, turn the nut continuously at a rate of 3 to 5 seconds per turn and take the torque reading on the fifth turn.

Turning torque: 0.05 To 1.96 N*m, (0.5 To 20 kgf*cm, 0.4 To 17 in.*Lbf) or less

- Check for any cracks and grease leaks on the ball joint dust cover.

Installation

- Install front no. 1 Stabilizer bar bush lh

- Install the bush.

Hint:

- Install each bush to the inner side of each bush stopper on the stabilizer bar.

- Install each bush with its slit facing the vehicle rear side.

- Remove front no. 1 Stabilizer bar bush rh

Hint:

Use the same procedures described for the lh side.

- Install front stabilizer bar

- Install the stabilizer bar to the crossmember.

- Install front suspension member brace front lh

- Install the member brace with the 4 bolt to the suspension member.

Torque: 87 n*m (887 kgf*cm, 64 ft.*Lbf)

- Install front suspension member brace front rh

Hint:

Use the same procedures described for the lh side.

- Install front stabilizer link assembly lh

- Install the link with the 2 nut.

Torque: 74 n*m (755 kgf*cm, 55 ft.*Lbf)

- Install front stabilizer link assembly rh

Hint:

Use the same procedures described for the lh side.

- Install front wheel torque: 103 n*m (1,050 kgf*cm, 76 ft.*Lbf)

- Stabilize suspension (see page sp-12)

Front lower ball joint

Front lower ball joint

Components

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Remove front wheel

Remove front speed sensor lh (for ...

Rear coil spring

Rear coil spring

Components

Removal

Hint:

Use the same procedures for the rh side and lh side.

The procedures listed below are for the lh side.

Remove rear wheel

Remove skid control sensor wire (fo ...

Other materials:

If you have a flat tire

Your vehicle is equipped with a spare tire. The flat tire can be

replaced with the spare tire.

WARNING

â– If you have a flat tire

Do not continue driving with a flat tire.

Driving even a short distance with a flat tire can damage the tire and the

wheel beyond repair, which could result in an accide ...

Front seat assembly (for manual seat)

Components

...

Short in driver side curtain shield squib circuit

Description

The driver side curtain shield squib circuit consists of the center airbag

sensor and the curtain shield

airbag lh.

The circuit instructs the srs to deploy when the deployment conditions are met.

These dtcs are recorded when a malfunction is detected in the driver side

cu ...