Toyota RAV4 (XA40) 2013-2018 Service Manual: Evaporative emission control system leak detected

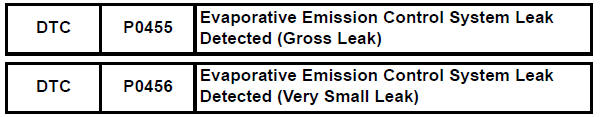

Dtc summary

Description

The description can be found in the evap (evaporative emission) system (see page es-335).

Inspection procedure

Refer to the evap system (see page es-340).

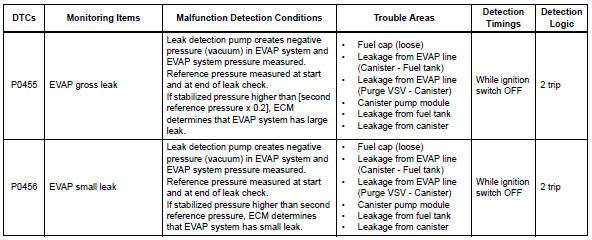

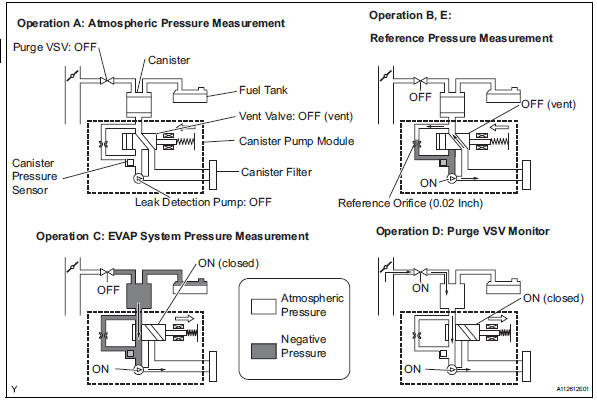

Monitor description

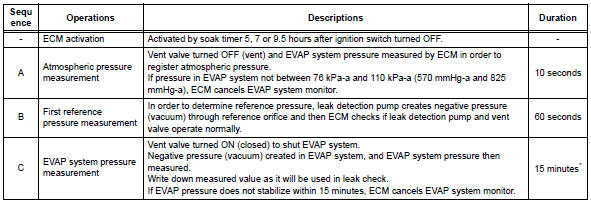

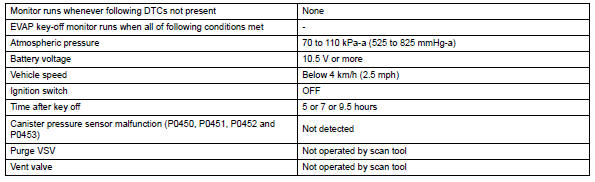

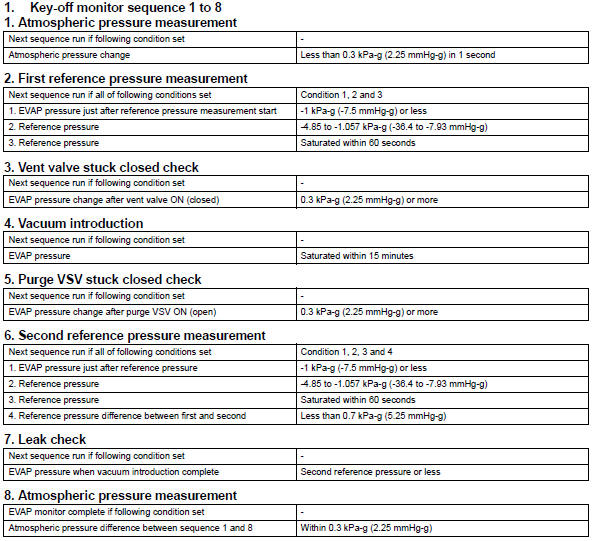

5 Hours* after the ignition switch is turned off, the leak detection pump creates negative pressure (vacuum) in the evap system. The ecm monitors for leaks and actuator malfunctions based on the evap pressure.

Hint:

*: If the engine coolant temperature is not below 35°c (95°f) 5 hours after the ignition switch is turned off, the monitor check starts 2 hours later. If it is still not below 35°c (95°f) 7 hours after the ignition switch is turned off, the monitor check starts 2.5 Hours later.

*: If only a small amount of fuel is in the fuel tank, it takes longer for the evap pressure to stabilize.

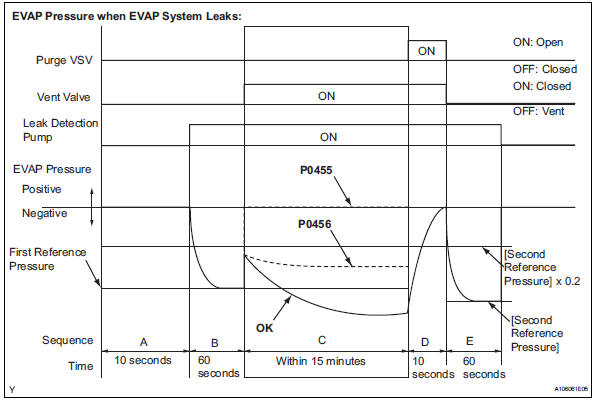

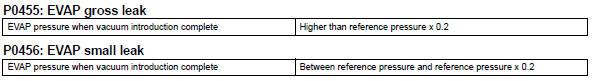

- P0455: evap gross leak

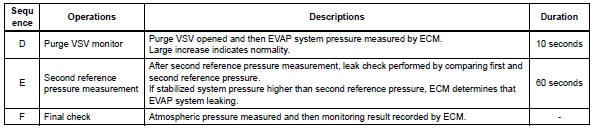

In operation c, the leak detection pump creates negative pressure (vacuum) in the evap system and the evap system pressure is measured. If the stabilized system pressure is higher than [second reference pressure x 0.2] (Near atmospheric pressure), the ecm determines that the evap system has a large leakage, illuminates the mil and sets the dtc (2 trip detection logic).

- P0456: evap very small leak

In operation c, the leak detection pump creates negative pressure (vacuum) in the evap system and the evap system pressure is measured. If the stabilized system pressure is higher than the second reference pressure, the ecm determines that the evap system has a small leakage, illuminates the mil and sets the dtc (2 trip detection logic).

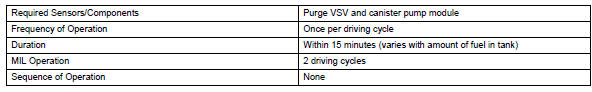

Monitor strategy

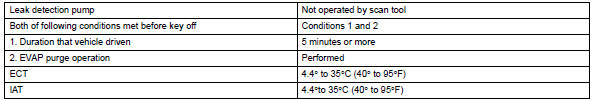

Typical enabling conditions

Typical malfunction thresholds

Monitor result

Refer to checking monitor status (see page es-17).

Evaporative emission control system pressure sensor

Evaporative emission control system pressure sensor

Dtc summary

Hint:

The canister pressure sensor is built into the canister pump module.

Description

The description can be found in the evap (evaporative emission) system (see

page es ...

Vehicle speed sensor "A"

Vehicle speed sensor "A"

description

The speed sensor detects the wheel speed and sends the appropriate signals to

the skid control ecu.

The skid control ecu converts these wheel speed signals into a 4-pulse signal ...

Other materials:

Emission inspection

and maintenance (i/m)

programs

Some states have vehicle emission inspection programs which

include obd (on board diagnostics) checks. The obd system

monitors the operation of the emission control system.

If the malfunction indicator lamp comes on

The obd system determines that a problem exists somewhere in the

emission contr ...

Terminals of ecu

Check sliding roof drive gear subassembly (sliding roof ecu)

Disconnect the p6 ecu connector.

Measure the resistance and voltage of the wire

harness side connector.

Reconnect the p6 ecu connector.

Measure the voltage of the connector.

If the result is not as speci ...

Reassembly

Install generator rotor assembly

Install the washer onto the generator rectifier end

frame.

Install the generator rotor onto the generator

rectifier end frame.

Using a 32 mm socket wrench and press, slowly

push the generator drive end frame onto the

generator ...